UPDATES & LEARNING

QatarEnergy, TotalEnergies kick off $13 bn project in Iraq

Tags: #Qatar #QatarEnergy ##TotalEnergies

Source; Qatar tribune

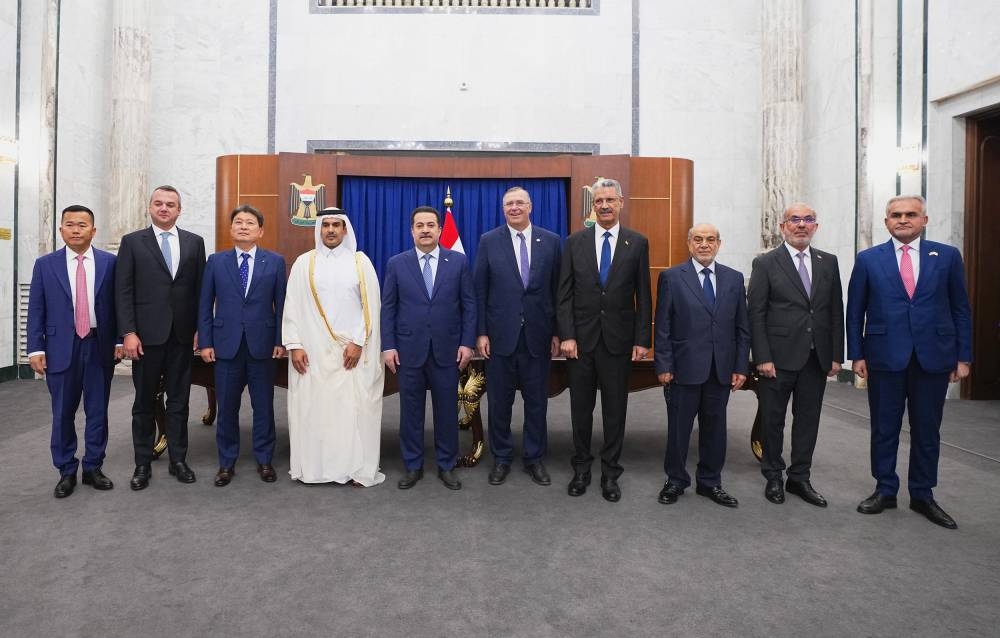

Minister of State for Energy Affairs, the President and CEO of QatarEnergy HE Saad Sherida Al-Kaabi, and Patrick Pouyanné, Chairman and CEO of TotalEnergies, met in Baghdad with Mohammed Shia Al-Sudani, the Prime Minister of Iraq, to announce the start of construction of the Common Seawater Supply Project (CSSP) and Phase 2 of the Artawi Oil Field Redevelopment project (Artawi Phase 2 Project).

The two projects represent the final major components of Iraq’s Gas Growth Integrated Project (GGIP), a multi-phase initiative aimed at enhancing the country’s energy infrastructure, currently being developed by the GGIP partners: QatarEnergy (25%), TotalEnergies (45%, operator), and Basra Oil Company (30%).

The signing took place during a special ceremony held under the patronage of Mohammed Shia Al-Sudani and attended by Minister Al-Kaabi, Hayyan Abdul Ghani Al-Sawad, the Iraqi Deputy Prime Minister for Energy Affairs and Minister of Oil, and senior Iraqi officials and executives from the three project partners.

- QatarEnergy, TotalEnergies, and Basra Oil Company started key GGIP projects in Iraq.

- The CSSP will supply seawater and reduce freshwater use, while Artawi Phase 2 will raise oil output by 2028.

- The GGIP will boost Iraq’s energy, gas recovery, and renewable development.

KBR wins detailed engineering contract for Qatar’s Bul Hanine field

Tags: #Saudi Arabia #Infra #NEOM #Qatar #QatarEnergy

Source: Oil & Gas Middle East

KBR has been awarded a detailed engineering services contract for the Bul Hanine oil and gas field offshore Qatar, a project that will see the company deliver design and engineering work for QatarEnergy’s EPIC development.

The Bul Hanine field lies roughly 120 kilometres east of Doha and is one of the country’s key offshore oilfields, playing a central role in sustaining Qatar’s production portfolio.

According to a news report by Offshore Energy, the redevelopment project is designed to extend the field’s production life, boost capacity, and deploy advanced technologies to maximise resource recovery. It represents a significant investment in maintaining Qatar’s long-term energy output and infrastructure resilience.

China’s Offshore Oil Engineering Company (COOEC) has also secured contracts for two segments of the same redevelopment initiative, underscoring the scale of Qatar’s offshore expansion efforts.

Jay Ibrahim, President of Sustainable Technology Solutions at KBR, said the company is proud to support a project that underpins the nation’s energy security and growth ambitions. “As we continue to focus large efforts on the Global South, where the need for energy production continues to be in demand, we are honoured to support the redevelopment of the Bul Hanine field,” he said, according to Offshore Energy.

He added that “with its proven offshore engineering expertise and successful delivery of projects across the Middle East, KBR is well-positioned to serve QatarEnergy”.

The Bul Hanine award follows closely after KBR secured an engineering and procurement services contract for a gas development project upgrade in Trinidad and Tobago, signalling the company’s expanding international portfolio across major hydrocarbon markets.

- KBR won a contract to deliver engineering services for QatarEnergy’s Bul Hanine offshore redevelopment.

- The project aims to extend the field’s life, boost production, and apply advanced technologies.

- COOEC also secured work, showing the scale of Qatar’s offshore expansion, while KBR grows its global project portfolio.

ADNOC Drilling Awarded More Than $3.4 Billion in Contracts to Drive Offshore Production Capacity

Tags: #UAE

Abu Dhabi National Oil Company (ADNOC) announced two contracts totalling more than $3.4 billion (AED12.6 billion) have been awarded to ADNOC Drilling to hire 8 jack-up offshore rigs. The contracts, valued at $1.5 billion (AED 5.6 billion) and $1.9 billion (AED 7 billion) respectively, awarded by ADNOC Offshore, will support the expansion of ADNOC’s crude oil production capacity to five million barrels per day (mmbpd) by 2030 and enable gas self-sufficiency for the UAE. Over the life of the 15-year contracts, ADNOC Drilling’s state-of-the-art rig fleet will enable ADNOC and its strategic international partners to further unlock Abu Dhabi’s offshore oil and gas resources, creating significant value for ADNOC, its partners and the UAE. Over 80% of the value of the awards will flow back into the UAE’s economy under ADNOC’s successful In-Country Value (ICV) program, supporting local economic growth and diversification. His Excellency Dr. Sultan Ahmed Al Jaber, Minister of Industry and Advanced Technology and ADNOC Managing Director and Group CEO, said: “This world-leading investment will significantly expand our drilling activity to accelerate growth, drive value and responsibly unlock the UAE’s resources in response to globally rising demand for energy. ADNOC Drilling’s state-of-the-art fleet and market-leading capabilities, will be a key enabler as ADNOC strengthens its position as a leading low-cost and low-carbon energy producer. We are focused on delivering on our 2030 strategy, in support of the directives of our wise leadership to grow and diversify the UAE’s economy.” The jack-up rigs will be hired along with manpower and equipment to support drilling operations across ADNOC’s offshore fields, which account for about half of ADNOC’s production capacity. ADNOC Drilling is the largest national drilling company in the Middle East by rig fleet size, with 105 owned rigs, including 27 offshore jack-up units, one of the largest operational jack-up fleets in the world. The company’s expansive rig fleet and market leading expertise remain key drivers in its ability to win and service large-scale drilling contracts for customers such as ADNOC Offshore, and to enable the unlocking of significant potential in Abu Dhabi’s waters. ADNOC recently awarded ADNOC Drilling two further substantial contracts totalling $2 billion (AED 7.49 billion) for integrated drilling services and the provision of Island Drilling Units at its Hail and Ghasha Gas Development Project.

- AUGUST 9, 2022

- Contact@adnoc.com

- www.Adnoc.com

Woqod- Qatar Fuel Company Q.P.S.C.

Tags: #Qatar #Oil & Gas #Energy

Qatar Fuel was formally created by virtue of Emiri decree no. 5 issued on 10 February 2002.Its assets were transferred from QatarEnergy's subsidiary National Oil Distribution Company (NODCO), which managed a refined petroleum product supply depot in Abu Hamour. In 2009, Qatar Fuel established a liquefied petroleum gas plant in Doha's Industrial Area. During an Extraordinary General Assembly held in June 2018, the company made the decision to increase non-Qatari ownership to 49% in order to attract investments. A budget of QR 634 million was allocated for 2018 to be earmarked for the construction of new filling stations and the development of currently existing ones. According to company officials, plans are in place to install 88 filling stations by the end of 2018 with a total of 100 by 2020.

- Woqod- Qatar Fuel Company Q.P.S.C.

- Email: sales@woqod.com

- Website: www.woqod.com

SWPC issued RFP for 150km Rayis – Rabigh IWTP Project

Tags: #Oman #Yemen #UAE

The project involves the construction of water transmission pipeline of capacity up to 500,000 cubic meters per day, and lengths of 150 km. As per the earlier notification, SWPC will conduct a competitive process to select a developer or developer consortium to develop the Project on a Build, Own, Operate and Transfer (BOOT) basis. The project company developing the Project will provide the entire transmission capacity to SWPC under a Water Transmission Agreement (WTA). The term of the WTA is expected to be up to 35 years. SWPC’s obligations under the WTA will be supported by a credit support agreement entered into by the Ministry of Finance on behalf of the Government of the Kingdom of Saudi Arabia. SWPC advised by Synergy Consulting IFA Inc. (as Lead and Financial Adviser), Amer Al Amr Law Firm (as Legal Adviser) and Fichtner GmbH & Co. KG (as Technical Adviser).

- AI in oil and gas field-cons pros

- testing

- how transforming technology

ADNOC Drilling Awarded More Than $3.4 Billion in Contracts to Drive Offshore Production Capacity

Tags: #ADNOC EPC #ADNOC projects

Abu Dhabi National Oil Company (ADNOC) announced two contracts totalling more than $3.4 billion (AED12.6 billion) have been awarded to ADNOC Drilling to hire 8 jack-up offshore rigs. The contracts, valued at $1.5 billion (AED 5.6 billion) and $1.9 billion (AED 7 billion) respectively, awarded by ADNOC Offshore, will support the expansion of ADNOC’s crude oil production capacity to five million barrels per day (mmbpd) by 2030 and enable gas self-sufficiency for the UAE. Over the life of the 15-year contracts, ADNOC Drilling’s state-of-the-art rig fleet will enable ADNOC and its strategic international partners to further unlock Abu Dhabi’s offshore oil and gas resources, creating significant value for ADNOC, its partners and the UAE. Over 80% of the value of the awards will flow back into the UAE’s economy under ADNOC’s successful In-Country Value (ICV) program, supporting local economic growth and diversification. His Excellency Dr. Sultan Ahmed Al Jaber, Minister of Industry and Advanced Technology and ADNOC Managing Director and Group CEO, said: “This world-leading investment will significantly expand our drilling activity to accelerate growth, drive value and responsibly unlock the UAE’s resources in response to globally rising demand for energy. ADNOC Drilling’s state-of-the-art fleet and market-leading capabilities, will be a key enabler as ADNOC strengthens its position as a leading low-cost and low-carbon energy producer. We are focused on delivering on our 2030 strategy, in support of the directives of our wise leadership to grow and diversify the UAE’s economy.” The jack-up rigs will be hired along with manpower and equipment to support drilling operations across ADNOC’s offshore fields, which account for about half of ADNOC’s production capacity. ADNOC Drilling is the largest national drilling company in the Middle East by rig fleet size, with 105 owned rigs, including 27 offshore jack-up units, one of the largest operational jack-up fleets in the world. The company’s expansive rig fleet and market leading expertise remain key drivers in its ability to win and service large-scale drilling contracts for customers such as ADNOC Offshore, and to enable the unlocking of significant potential in Abu Dhabi’s waters. ADNOC recently awarded ADNOC Drilling two further substantial contracts totalling $2 billion (AED 7.49 billion) for integrated drilling services and the provision of Island Drilling Units at its Hail and Ghasha Gas Development Project.Abu Dhabi National Oil Company (ADNOC) announced two contracts totalling more than $3.4 billion (AED12.6 billion) have been awarded to ADNOC Drilling to hire 8 jack-up offshore rigs. The contracts, valued at $1.5 billion (AED 5.6 billion) and $1.9 billion (AED 7 billion) respectively, awarded by ADNOC Offshore, will support the expansion of ADNOC’s crude oil production capacity to five million barrels per day (mmbpd) by 2030 and enable gas self-sufficiency for the UAE. Over the life of the 15-year contracts, ADNOC Drilling’s state-of-the-art rig fleet will enable ADNOC and its strategic international partners to further unlock Abu Dhabi’s offshore oil and gas resources, creating significant value for ADNOC, its partners and the UAE. Over 80% of the value of the awards will flow back into the UAE’s economy under ADNOC’s successful In-Country Value (ICV) program, supporting local economic growth and diversification. His Excellency Dr. Sultan Ahmed Al Jaber, Minister of Industry and Advanced Technology and ADNOC Managing Director and Group CEO, said: “This world-leading investment will significantly expand our drilling activity to accelerate growth, drive value and responsibly unlock the UAE’s resources in response to globally rising demand for energy. ADNOC Drilling’s state-of-the-art fleet and market-leading capabilities, will be a key enabler as ADNOC strengthens its position as a leading low-cost and low-carbon energy producer. We are focused on delivering on our 2030 strategy, in support of the directives of our wise leadership to grow and diversify the UAE’s economy.” The jack-up rigs will be hired along with manpower and equipment to support drilling operations across ADNOC’s offshore fields, which account for about half of ADNOC’s production capacity. ADNOC Drilling is the largest national drilling company in the Middle East by rig fleet size, with 105 owned rigs, including 27 offshore jack-up units, one of the largest operational jack-up fleets in the world. The company’s expansive rig fleet and market leading expertise remain key drivers in its ability to win and service large-scale drilling contracts for customers such as ADNOC Offshore, and to enable the unlocking of significant potential in Abu Dhabi’s waters. ADNOC recently awarded ADNOC Drilling two further substantial contracts totalling $2 billion (AED 7.49 billion) for integrated drilling services and the provision of Island Drilling Units at its Hail and Ghasha Gas Development Project.

- AUGUST 9, 2022

Petrofac extends relationship with NEO Energy

Tags: #Petrofaac

Updated 12/09/2022 -Petrofac, a leading international service provider to the energy industry, announced a five-year contract extension for Well Management and Well Operator Services with NEO Energy. Petrofac will provide a five-year framework for Well Management and Well Operator support for 27 wells across the Affleck, Balloch, Dumbarton, Lochranza and Finlaggan fields located in the Central North Sea, UK. The contract also positions Petrofac to support future well construction and intervention campaigns. Petrofac is a leading international service provider to the energy industry, with a diverse client portfolio including many of the world’s leading energy companies. Petrofac designs, builds, manages and maintains oil, gas, refining, petrochemicals and renewable energy infrastructure.

Our purpose is to enable our clients to meet the world’s evolving energy needs. Petrofac’s core markets are in the Middle East and North Africa (MENA) region and the UK North Sea, where we have built a long and successful track record of safe, reliable and innovative execution, underpinned by a cost effective and local delivery model with a strong focus on in-country value. We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.Our purpose is to enable our clients to meet the world’s evolving energy needs. Petrofac’s core markets are in the Middle East and North Africa (MENA) region and the UK North Sea, where we have built a long and successful track record of safe, reliable and innovative execution, underpinned by a cost effective and local delivery model with a strong focus on in-country value. We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.

Our purpose is to enable our clients to meet the world’s evolving energy needs. Petrofac’s core markets are in the Middle East and North Africa (MENA) region and the UK North Sea, where we have built a long and successful track record of safe, reliable and innovative execution, underpinned by a cost effective and local delivery model with a strong focus on in-country value. We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.We operate in several other significant markets, including India, South East Asia and the United States. We have 8,500 employees based across 31 offices globally.

Nextchem’s MyRechemical awarded an engineering contract by Alia Servizi Ambientali for a waste to

Tags: #chemical

Maire Tecnimont S.p.A. announces that its subsidiary MyRechemical, NextChem’s subsidiary dedicated to Waste-to-Chemicals technologies, has been awarded by Alia Servizi Ambientali S.p.A. a basic engineering contract for a waste to methanol and hydrogen plant to be located in Empoli (Tuscany), Italy. The scope of work includes basic engineering design of the plant and the provision of necessary documentation to start the plant’s public authorization process with the Tuscany region. The basic engineering phase is expected to be completed by the end of 2022. Once authorized and completed, the plant will process 256,000 tons/yr. of non-recyclable waste and will produce 125,000 tons/yr. of methanol and 1,400 tons/yr. of hydrogen. The plant will benefit from MyRechemical’s chemical conversion technology which allows the recovery of waste that cannot be mechanically recycled, or other types of unsortable dry waste (i.e. Refuse Derived Fuel – RDF). The carbon and hydrogen contained in the waste are converted through a gasification process into a synthesis gas, which is used to produce low-carbon methanol and hydrogen. This process avoids the emission of pollutants in the atmosphere. Methanol is used as an alternative fuel for sustainable mobility or as a secondary raw material in the chemicals and manufacturing industries. Hydrogen can be used in low-carbon industrial processes to decarbonize hard-to-abate and energy intensive industries. Alessandro Bernini, Chief Executive Officer of Maire Tecnimont Group and NextChem, commented: “This is one of the more interesting waste-to-chemicals initiatives that Maire Tecnimont is developing in Italy. This is the first application worldwide of an integrated technological scheme that allows to produce methanol from waste for sustainable mobility and hydrogen that will substitute methane in glass production processes, enabling both recycling and industrial symbiosis. It responds to the core need of circular economy and creates the bases of a new era of waste as a resource”. “It will be possible to push the limits forward in recovering material from waste only by using more technology and innovation. We have signed a strategic partnership with Maire Tecnimont, leader in the Italian chemistry tradition”, commented Alberto Irace, Chief Executive Officer of Alia, “This represents a model of strategic alliance for circularity where Maire Tecnimont, Zignago, Suez and Alia, all leading companies in technology and industry, are joining their forces to design and realize a sustainable future”.

Maire Tecnimont S.p.A. announces that its subsidiary MyRechemical, NextChem’s subsidiary dedicated to Waste-to-Chemicals technologies, has been awarded by Alia Servizi Ambientali S.p.A. a basic engineering contract for a waste to methanol and hydrogen plant to be located in Empoli (Tuscany), Italy. The scope of work includes basic engineering design of the plant and the provision of necessary documentation to start the plant’s public authorization process with the Tuscany region. The basic engineering phase is expected to be completed by the end of 2022. Once authorized and completed, the plant will process 256,000 tons/yr. of non-recyclable waste and will produce 125,000 tons/yr. of methanol and 1,400 tons/yr. of hydrogen. The plant will benefit from MyRechemical’s chemical conversion technology which allows the recovery of waste that cannot be mechanically recycled, or other types of unsortable dry waste (i.e. Refuse Derived Fuel – RDF). The carbon and hydrogen contained in the waste are converted through a gasification process into a synthesis gas, which is used to produce low-carbon methanol and hydrogen. This process avoids the emission of pollutants in the atmosphere. Methanol is used as an alternative fuel for sustainable mobility or as a secondary raw material in the chemicals and manufacturing industries. Hydrogen can be used in low-carbon industrial processes to decarbonize hard-to-abate and energy intensive industries. Alessandro Bernini, Chief Executive Officer of Maire Tecnimont Group and NextChem, commented: “This is one of the more interesting waste-to-chemicals initiatives that Maire Tecnimont is developing in Italy. This is the first application worldwide of an integrated technological scheme that allows to produce methanol from waste for sustainable mobility and hydrogen that will substitute methane in glass production processes, enabling both recycling and industrial symbiosis. It responds to the core need of circular economy and creates the bases of a new era of waste as a resource”. “It will be possible to push the limits forward in recovering material from waste only by using more technology and innovation. We have signed a strategic partnership with Maire Tecnimont, leader in the Italian chemistry tradition”, commented Alberto Irace, Chief Executive Officer of Alia, “This represents a model of strategic alliance for circularity where Maire Tecnimont, Zignago, Suez and Alia, all leading companies in technology and industry, are joining their forces to design and realize a sustainable future”.